Universal ChemicalsManufactures of

|

|||||||||

|

|||||||

![]()

Interpretation

of reaction of Alum and Sodium Aluminate in Water Treatment.

-

to produce polyaluminium hydroxide (pH region 7 to 8)

pH

The best floculation effect for natural waters is generally experienced in the

pH 6.0 to 8.0 range according to many investigators. The isoelectric point of

alumina in its hydroxide form is accepted as 7.4 pH. This corresponds to the

point of minimum solubility of aluminium hydroxide.

Coagulation tests on waters should initially use a mix of chemicals to achieve

a water pH of 7.4

Rate of Reaction

The higher the total concentration of aluminium salts within the 6.0 to 8.0 pH

range the faster pin point floc formation and floc build occurs.

At higher pH than 8.0 flocs can be produced dependant on total reactant concentration.

Other chemicals in opposition

Combinations of inorganic chemicals can be used with sodium aluminate to

achieve flocculation polymerisation in situ. A largley unexplored chemical

mechanism. Chemists investigating drinking water purification by empirical Jar

Test or pilot plant techniques need to apply sodium aluminate liquor correctly

at appropriate pH levels.

A range of inorganics - ferrics, polyalums or strong acids such as sulphate and

hydrochloric can be used to produce the same effect as aluminium sulphate or

chloride in opposition.

Comment

The representation of the coagulation reaction in the Hydrous Alumina diagram

is for a system at equilibrium and involving a fixed dose of reactants. With

materials in opposition, for example alum v aluminate, a wide range of alumina

polymer is achievable provided pH's close to neutral, are maintained.

In current full scale practise pH's are chosen to achieve particular results,

for example below 7.0 may be used, because it is claimed to achieve colour

removal. The availability of sodium aluminate liquor creates opportunities for

beneficial changes to be made in pH. The material can achieve higher pH's which

are still in the coagulation range pH 7.4 to 8.0 thus giving pH's which are

'buffered' when aluminate is applied. This is a special feature not available

to other coagulants, organic or inorganic.

In working to a specific pH the ratio of alum to SAL is adjusted so that the pH

required is achieved while maintaining the same total dose of in situ polyaluminium

floc.

Chemical Balances

The reaction between alum (8%) and sodium aluminate liquor (20%) requires an

Alum to Aluminate ratio of 1.8 to 1.0 by weight

· In tonnes - 1.8 tonne Alum to 1.0 tonne Aluminate · Alumina content - Alum

(8% soln) - contains - 0.144 tonnes alumina - Aluminate (20% soln) - contains -

0.200 tonnes alumina Total = 0.344 tonnes alumina

This total of 0.344 tonne is all active alumina and inclusive in the

flocculation process.

For other chemicals it is suggested determination of the relative amounts

should be determined by titration or contact Universal Chemicals

NB Acidic materials should be of the strong acid type. Weak acids and

barcarbonates do not give precise control due to pH spread. (strong acid - weak

base theory)

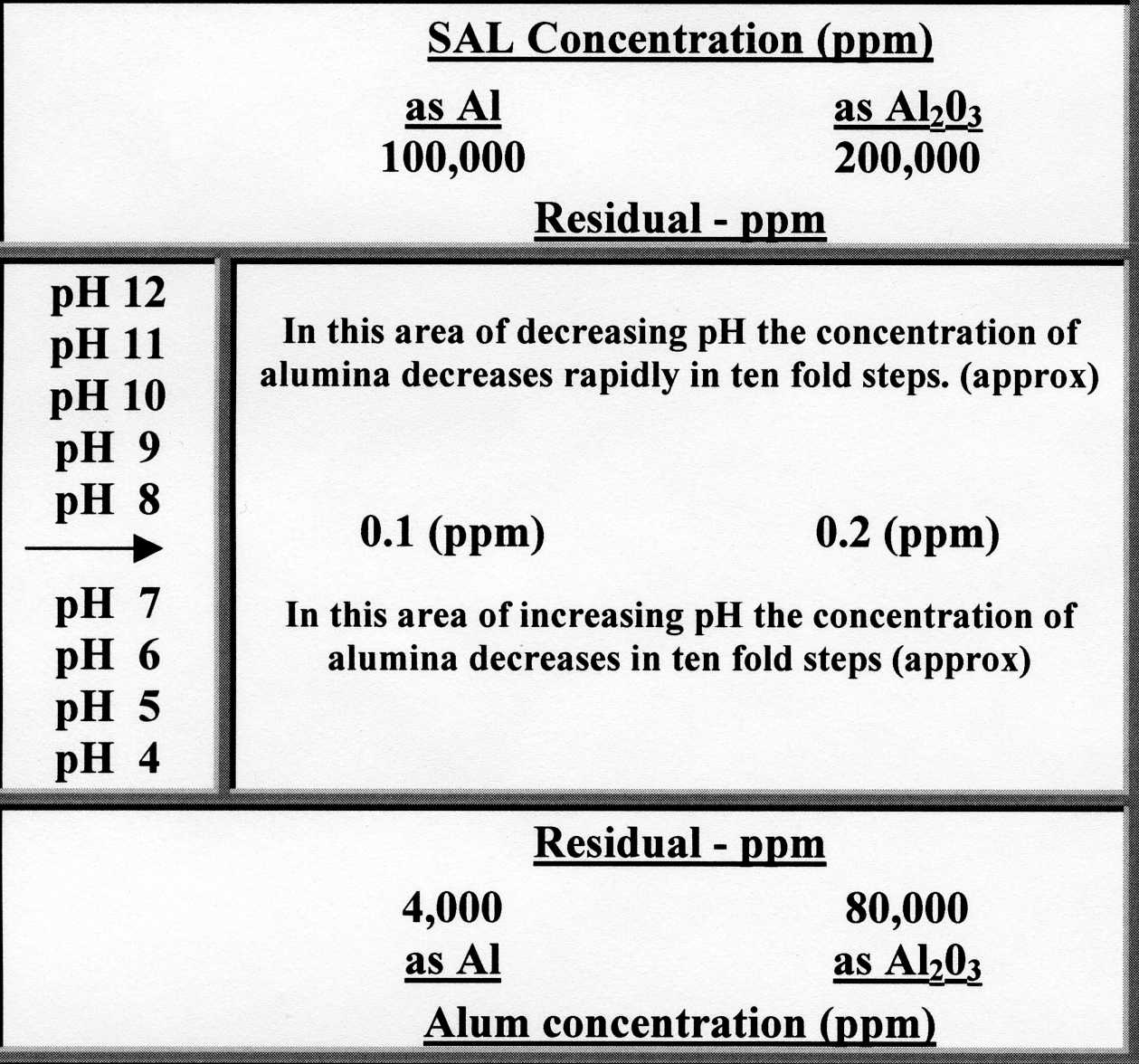

The above gives an approximation of the solubility of alumina species in water

against pH, also the very low polyhydroxy alumina level in solution with

neutral coagulation practise.